DiversaCut 2110A® Dicer

Choose from 3 different models

- Featured left to right above: DiversaCut 2110A with Large Product Input, NEW DiversaCut 2110A with Conveyor Discharge, and standard DiversaCut 2110A Dicer.

- The DiversaCut 2110A® Dicer dices, strips, slices, granulates, and shreds at high production capacities.

- All 3 models offer cost-savings by limiting the need for pre-cutting of products. Standard DiversaCut 2110A and Conveyor Discharge both accept products up to 10" (254 mm) in any dimension. Large Product Input machine accepts products as large as 14" (356 mm) in diameter.

- All models feature high capacity production capabilities and continuous operation for uninterrupted production. The compact cutting zone, completely separate from the mechanical zone establishes precision cuts as the product moves throughout the process. Slice adjustment dials and locks in the slice size. Adjustable collars on circular and crosscut spindles provide fine-tuning for ultimate precision.

Applications

DiversaCut 2110A® Dicer (Standard)

The DiversaCut 2110A Dicer (above, right) accepts a maximum infeed product of 10" (254 mm) in any dimension and offers cost-savings by eliminating the need to precut products. Boundless versatility extends across food industries. Widely sold to reduce vegetables/fruits, bakery ingredients, dairy inclusions, meat/poultry/seafood/pet food, and alternative products.

This dicer may be equipped with either a 5 (3.7 kW) or a 10 (7.5 kW) horsepower motor. The machine features continuous operation for uninterrupted production and is designed for easy cleanup and maintenance. The crosscut knife spindle in conjunction with the other cutting components creates a compact cutting zone establishing precision cuts as the product moves throughout the process.

NEW! DiversaCut 2110A® Dicer with Discharge Conveyor

The DiversaCut 2110A (with Conveyor) Dicer (above, middle) offers a turnkey approach to processors. It accepts a maximum infeed product of 10" (254 mm) in any dimension and offers cost savings by eliminating the need to precut products. The built-in conveyor guarantees a successful transfer point to maximize product quality and improve yield. The conveyor facilitates batch processing into totes or onto conveying systems or platforms. The new machine also eases routine servicing by maintaining the machine at floor level.

The DiversaCut series offers boundless versatility across food industries. DiversaCut models are widely sold to reduce vegetables/fruits, bakery ingredients, dairy inclusions, meat/poultry/seafood/pet food, and alternative plant-based products.

The dicer is equipped with a 5 HP (3.7 kW) motor and 1/4 HP (.19 kW) conveyor motor. The machine features continuous operation for uninterrupted production and is designed for easy cleanup and maintenance. The tight proximity of each cutting station in relation to the next creates a compact cutting zone. This results in precision cuts as the product moves throughout the process.

DiversaCut 2110A® Dicer with Large Product Input

Urschel delivers a targeted solution to processing whole heads of leafy vegetables — the DiversaCut 2110A® Dicer specially equipped with a large feed hopper (above, left) and a new type of impeller. Working with leading fresh-cut processors, this new development alleviates precutting and minimizes product handling.

This DiversaCut 2110A Large Product Input (MDCA, LPI) accepts products as large as 14" (356 mm) in diameter. This machine is available through our Engineering Certified Print Program – a specialty service geared toward producing ideal machines for individual processing lines/configurations. This machine is designed to interlock with product takeaway devices.

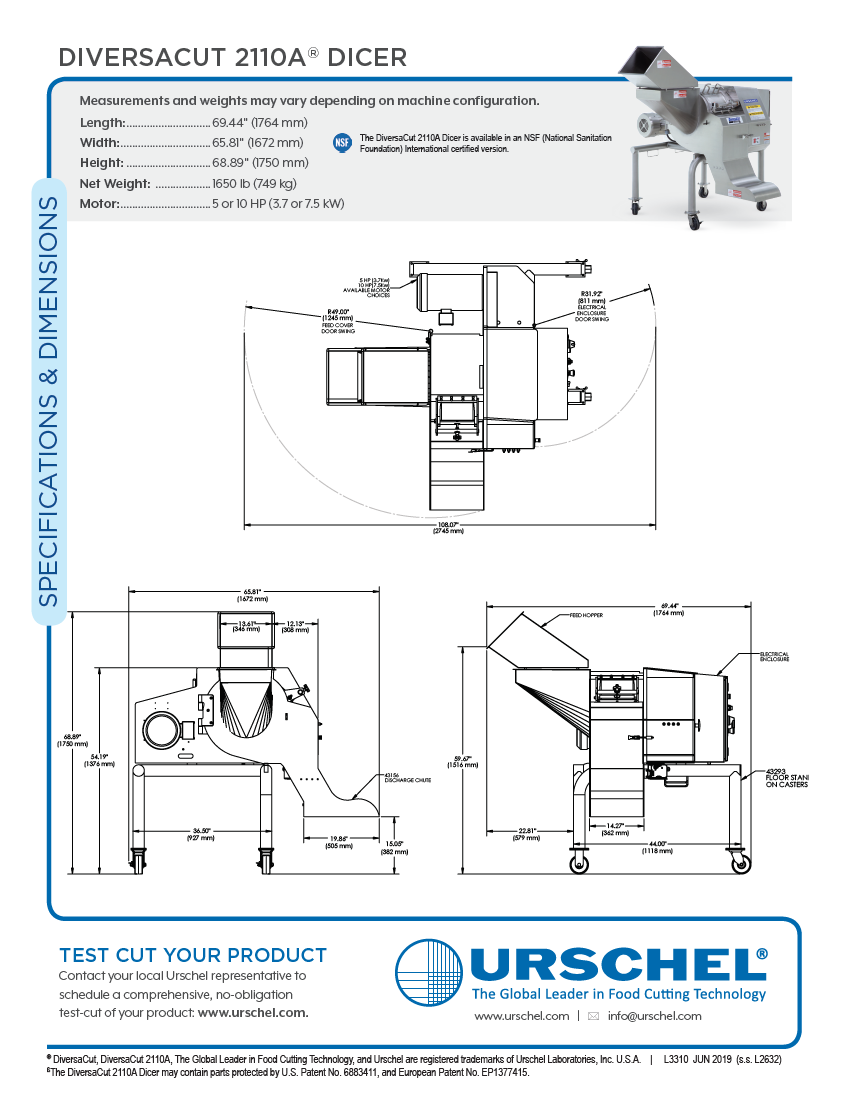

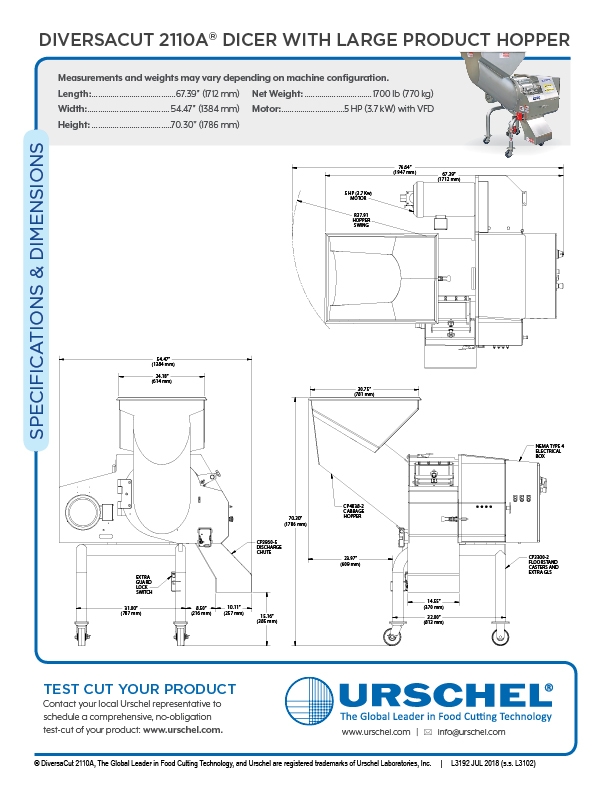

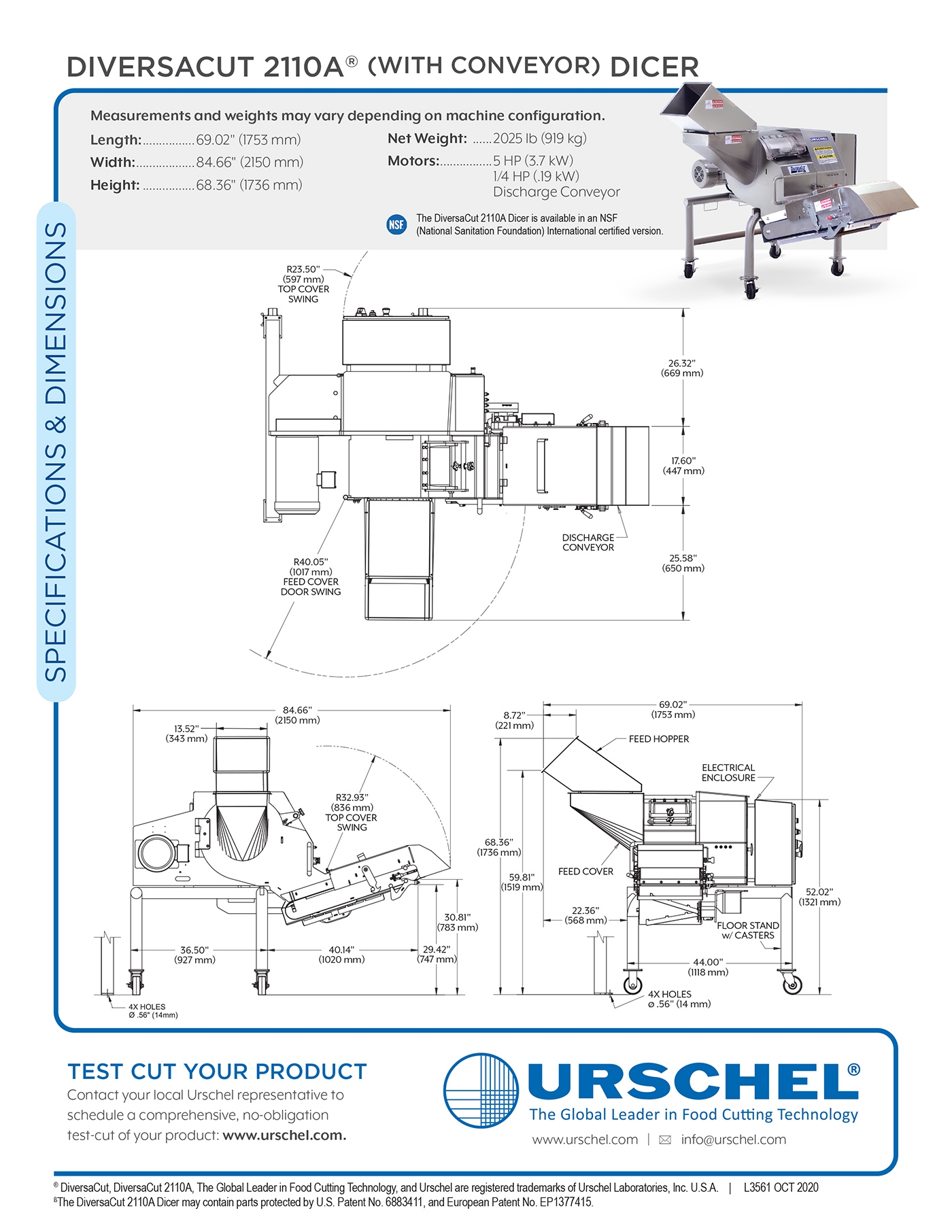

Machine Specs

DiversaCut 2110A® Dicer

DiversaCut 2110A® Large Product Input

NEW! DiversaCut 2110A® Dicer with Discharge Conveyor

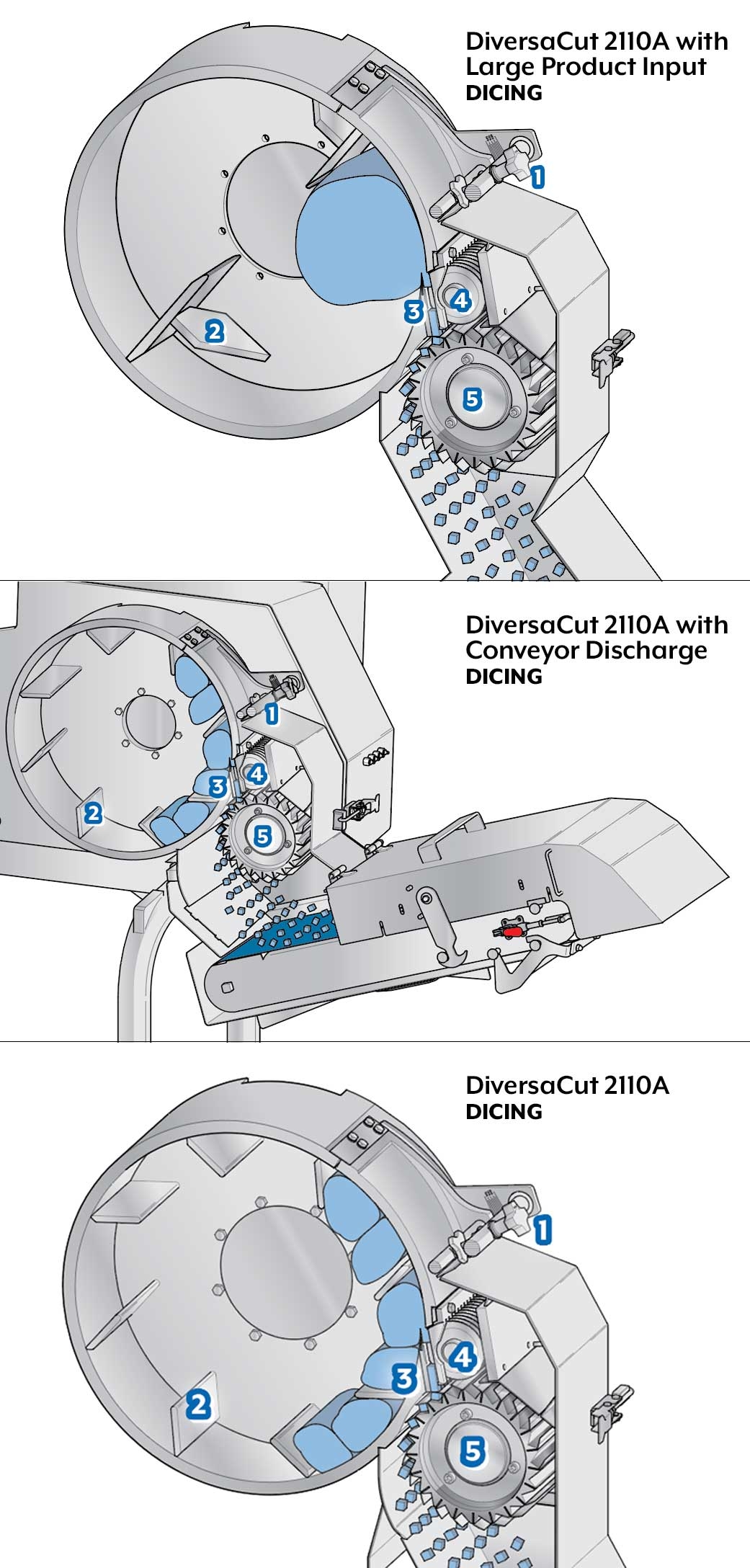

Operating Principle

DiversaCut 2110A® Dicers

- Slice Adjustment Knob

- Impeller Paddles

- Slicing Knife

- Circular Knives

- Crosscut Knives

Types of Cuts

Various cutting set-ups available depending on the DiversaCut 2110A model.

Check individual machine model specifications or contact your local Urschel office for more information.

SLICES

Flat or Crinkle: 1/16 to 1" (1.6 to 25.4 mm). The machine can make a full range of slices by removing the crosscut and circular knife spindles.

DICES/GRANULATIONS

A slicing knife, circular knife spindle, and crosscut knife spindle are used for dicing. Changing the dice size is done by using the required cutting spindles and adjusting the slice thickness.

Circular knife cuts

1/8 to 3" (3.2 to 76.2 mm)

Crosscut knife cuts

3/32 to 3-1/2" (2.4 to 88.9 mm)

Crosscut knife crinkle cuts (.076" depth)

9/32 to .583" (7.1 to 14.8 mm)

Crosscut knife deep crinkle cuts (.125" or .145" depth)

3/8 to 1/2" (9.5 to 12.7 mm)

Crosscut knife V-cuts

5/16 to 1/2" (7.9 to 12.7 mm)

STRIP CUTS - STANDARD DIVERSACUT 2110A & DIVERSACUT 2110A WITH CONVEYOR DISCHARGE

Flat and crinkle strip cuts in a variety of widths can be made by removing either the crosscut knife spindle or circular knife spindle assembly.

SHREDS - STANDARD DIVERSACUT 2110A & DIVERSACUT 2110A WITH CONVEYOR DISCHARGE

Fine, medium, and coarse shreds can be produced on hot or chilled cooked meat products. To produce shreds, the crosscut spindle is replaced with a shredding disc spindle.

STRIP CUTS/SHREDS - DIVERSACUT 2110A LARGE PRODUCT INPUT MACHINE

Leafy vegetables strips or shreds produced by removing either the crosscut knife spindle or the circular knife spindle. Combinations of circular knives or crosscut knives may be used to shorten the length of the strips.